DDEC III and DDEC IV ecms went on everything from Industrial 4 cylinder natural gas engines to 24 cylinder 2 stroke marine engines. Owners and techs of DDEC powered industrial or marine engines almost always know what engine they have so most of the engine information I’ve got on these pages are to help with the more difficult to identify Series 60 engines. No J1939 or EGR engine functions or 1998 or newer Series 60 programming are available to DDEC III ecms.

DDEC IV Series 60, 50, & Series 2000 programming/Tuning services

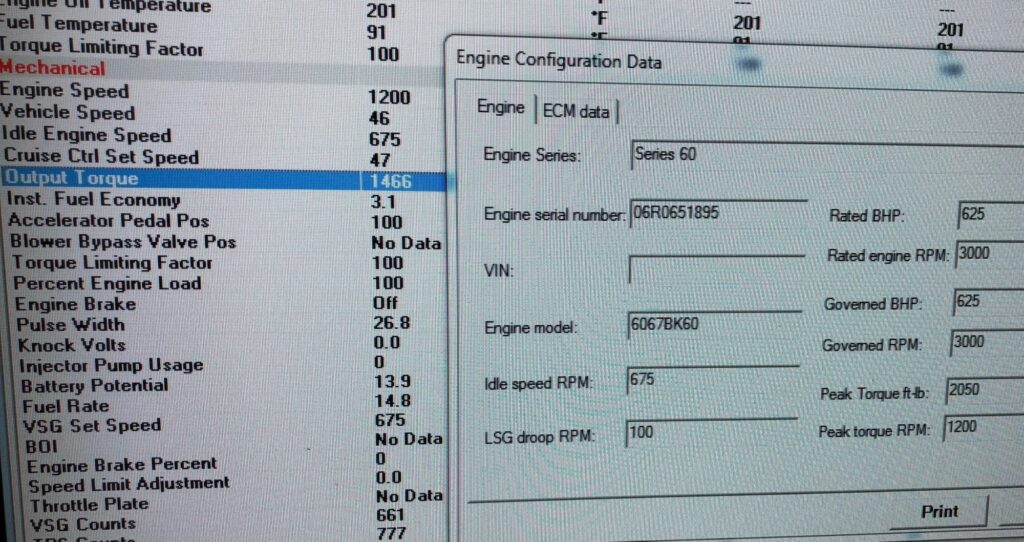

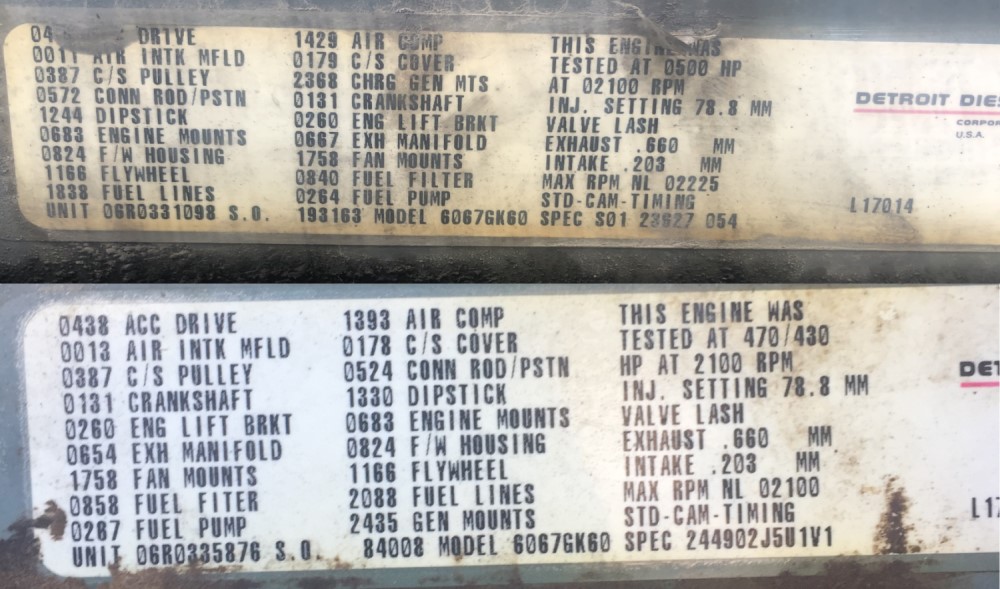

The photo below is of a bench test on a tune that had 2050ftlbs@1200rpm written in the data tag but was only making 1466ftlbs at 100 percent load. Even before the attempt was made to turn up the horsepower was made torque was lost because the base program was changed to an engine that was not compatible. was About a third of the programming work I do is fixing the programming mistakes of the last guy who plugged into it. It’s been my experience that most ECM tuning shops other than Detroit Diesel are not aware or just ignore the differences between Detroit engines, especially the Series 60 engines. The Series 60 that suffers the worst from this is the more common variation of the 1995 GK60. The biggest factory program available for the more common variation had peak power set to 470hp@2110rpm and 1550ftlbs@1200rpm for peak torque. There was also a less common 1995 GK60 set to 500hp but if an inexperienced tuner overwrites a GK60 that came with a 470hp program with the 500hp GK60 program then horsepower will drop to about 440 and torque will drop to about 1400ftlbs. Why? Because the 500hp GK60 runs a larger injector compared to what injector is factory in a 470hp GK60.

Before I get into any engine side programming on any DDEC that was previously tuned I like to verify the engine serial number, the injectors, the camshaft and the piston and rod assembly. That information is encoded on the valve cover stickers and if the parts have been kept factory will do most of the work identifying the engine. If an engine serial number was enough. They wouldn’t print valve cover stickers. The easiest way is to text over photos of the valve cover stickers as long as the valve cover is original and the injectors, cam, and pistons in the engine are correct for that engine family and build date. The single most critical step isn’t the I have great respect for the work Detroit did on these engines and whenever possible I use the bone stock factory program as the foundation of any engine side programming I do. The Identifying the engine The process of building a custom program from

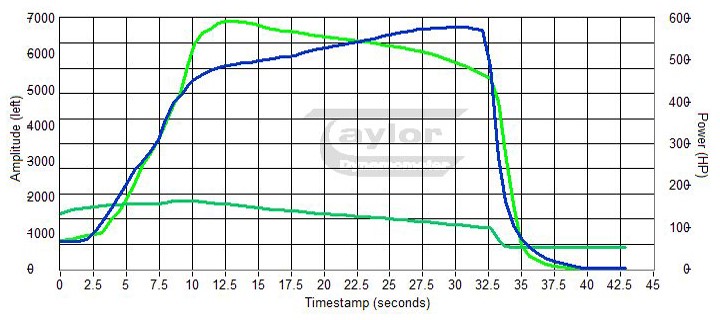

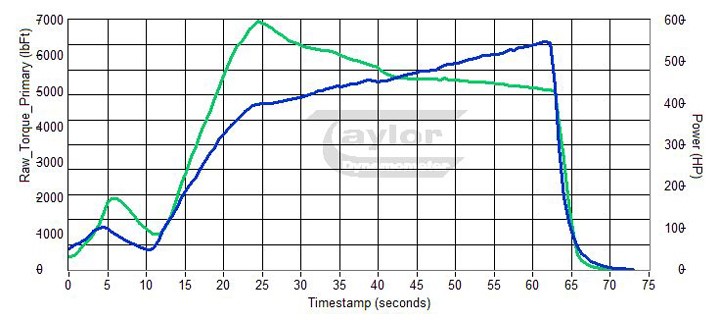

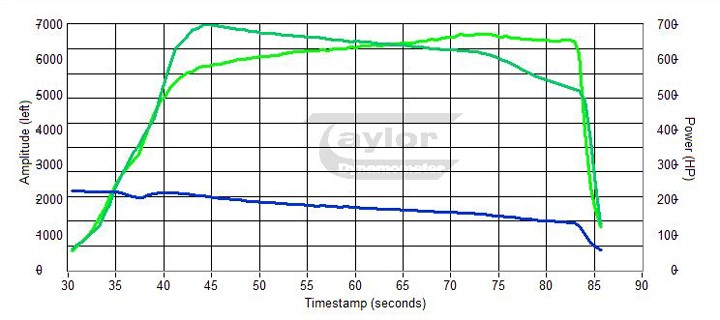

The dynamometer graphs you see are horsepower and torque at the rear wheels. Wheel or roller torque numbers (sometimes labeled Raw torque) are very high because the rear end ratio and tire size acts as a torque multiplier. The rear end ratio, tire size, transmission gearing and drivetrain losses make roller (wheel) torque and wheel horsepower less accurate and harder to compare than flywheel torque and flywheel horsepower. So the only time I use roller torque and roller horsepower is when referencing a chassis dynamometer test. For everything else I use flywheel torque and flywheel horsepower.

Generally, the higher the peak power and peak torque go the more heat builds up in the engine and the more careful the operator has to be to keep it cool. The table below are three of the most popular peak power and peak torque settings by engine. Not all engines in a given engine family are programmed with the same peak power and peak torque from the factory. If you are not sure what you want you are better off being conservative. I don’t like to talk anyone into numbers they aren’t comfortable with. DCS can also program most DDEC IVs with a three in one Triple play switchable programming that features on the fly selectable program changes to horsepower, torque, injection timing, rpm limit, and engine response. That way you can make some adjustments to the power and torque without needing reprogramming.

| Most popular by S60 engine | Factory Stock / or Economy opt | Mid Power setting (Flywheel HP) | High Power setting(FlywheelHP) |

| 1991 12.7 6067GK40 (conv only) | 400hp@1800 1450ftlbs@1200 | 450hp@2100 1550ftlbs@1200 | 500hp@2100 1600ftlbs@1200 |

| 1992 12.7 6067GK40 (conv only) | 450hp@2100 1450ftlbs@1200 | 475hp@2100 1550ftlbs@1200 | 500hp@2100 1650ftlbs@1200 |

| 1993 12.7 6067GK40 (conv only) | 450hp@2100 1450ftlbs@1200 | 475hp@2100 1550ftlbs@1200 | 500hp@2100 1650ftlbs@1200 |

| 1994 12.7 6067GK60 | 360hp@1800 1450ftlbs@1200 | 500hp@2100 1600ftlbs@1200 | 525hp@2100 1750ftlbs@1200 |

| 1994 11.1 6067WK60* | 330hp@1800 1150ftlbs@1200 | 400hp@2100 1400ftlbs@1200 | 450hp@2100 1500ftlbs@1350 |

| 1994 11.1 6067SK60* | 350hp@2100 1350ftlbs@1200 | 400hp@2100 1400ftlbs@1200 | 450hp@2100 1500ftlbs@1350 |

| 1995 12.7 6067GK60 | 430hp@2100 1550ftlbs@1200 | 525hp@2100 1700ftlbs@1200 | 550hp@2100 1850ftlbs@1200 |

| 1995 12.7 6067GK60 v2 | 500hp@2100 1550ftlbs@1200 | 525hp@2100 1700ftlbs@1200 | 550hp@2100 1850ftlbs@1200 |

| 1995 11.1 6067WK60* | 330hp@1800 1150ftlbs@1200 | 375hp@2100 1350ftlbs@1200 | 400hp@2100 1500ftlbs@1350 |

| 1995 11.1 6067SK60* | 400hp@2100 1350ftlbs@1200 | 425hp@2100 1400ftlbs@1200 | 450hp@2100 1500ftlbs@1350 |

| 1996 12.7 6067GK60 | 470hp@2100 1450ftlbs@1200 | 525hp@2100 1750ftlbs@1200 | 550hp@2100 1850ftlbs@1200 |

| 1996 12.7 6067GK60 v2 | 500hp@2100 1550ftlbs@1200 | 525hp@2100 1750ftlbs@1200 | 550hp@2100 1850ftlbs@1200 |

| 1996 11.1 6067WK60* | 350hp@2100 1350ftlbs@1200 | 400hp@2100 1400ftlbs@1200 | 450hp@2100 1500ftlbs@1350 |

| 1996 11.1 6067SK60* | 350hp@1800 1250ftlbs@1200 | 400hp@2100 1400ftlbs@1200 | 450hp@2100 1500ftlbs@1350 |

| 1997 12.7 6067GK60 | 500hp@2100 1650ftlbs@1200 | 525hp@2100 1750ftlbs@1200 | 550hp@2100 1850ftlbs@1200 v2 |

| 1997 11.1 6067WK60* | 365hp@1800 1350ftlbs@1200 | 400hp@2100 1400ftlbs@1200 | 450hp@2100 1500ftlbs@1350 |

| 1997 11.1 6067SK60* | 330hp@2100 1350ftlbs@1200 | 400hp@2100 1400ftlbs@1200 | 450hp@2100 1500ftlbs@1350 |

| 1998 12.7 6067TK60* | 430hp@2100 1550ftlbs@1200 | 515hp@2100 1750ftlbs@1200 | 550hp@2100 1850ftlbs@1200 |

| 1998 12.7 6067PK60 | 500hp@2100 1650ftlbs@1200 | 580hp@2100 1850ftlbs@1200 | 625hp@2100 2000ftlbs@1200 |

| 1998 11.1 6067EK60* | 350hp@2100 1250ftlbs@1200 | 400hp@2100 1400ftlbs@1200 | 450hp@2100 1450ftlbs@1350 |

| 1999 12.7 6067MK60* | 470hp@2100 1550ftlbs@1200 | 525hp@2100 1700ftlbs@1200 | 550hp@2100 1850ftlbs@1200 |

| 1999 12.7 6067BK60 | 500hp@2100 1650ftlbs@1200 | 580hp@2100 1850ftlbs@1200 | 625hp@2100 2000ftlbs@1200 |

| 1999 11.1 6067LK60* | 350hp@2100 1250ftlbs@1200 | 400hp@2100 1400ftlbs@1200 | 450hp@2100 1500ftlbs@1350 |

| 2000 12.7 6067MK60* | 430hp@2100 1450ftlbs@1200 | 525hp@2100 1700ftlbs@1200 | 550hp@2100 1850ftlbs@1200 |

| 2000 12.7 6067BK60 | 500hp@2100 1650ftlbs@1200 | 580hp@2100 1850ftlbs@1200 | 625hp@2100 2000ftlbs@1200 |

| 2000 14.0 6067HK60 | 575hp@2100 1850ftlbs@1200 | 650hp@2100 2000ftlbs@1200 | 750hp@2100 2150ftlbs@1200 |

| 2001 12.7 6067MK60 | 430hp@2100 1550ftlbs@1200 | 525hp@2100 1750ftlbs@1200 | 600hp@2100 1900ftlbs@1200 |

| 2001 12.7 6067BK60 | 500hp@2100 1650ftlbs@1200 | 550hp@2100 1850ftlbs@1200 | 600hp@2100 2000ftlbs@1350 |

| 2001 14.0 6067HK60 | 550hp@2100 1850ftlbs@1200 | 600hp@2100 2000ftlbs@1200 | 700hp@2100 2100ftlbs@1200 |

| 2002 12.7 6067MK60 | 430hp@2100 1550ftlbs@1200 | 525hp@2100 1850ftlbs@1200 | 600hp@2100 1900ftlbs@1200 |

| 2002 12.7 6067BK60 | 500hp@2100 1650ftlbs@1200 | 550hp@2100 1850ftlbs@1200 | 600hp@2100 2000ftlbs@1350 |

| 2002 14.0 6067HK60 | 550hp@2100 1850ftlbs@1200 | 650hp@2100 2050ftlbs@1200 | 700hp@2100 2100ftlbs@1200 |

| 2003 12.7 6067MK2E (EGR) | 400hp@2100 1450ftlbs@1200 | No tuning options at this time | No tuning options at this time |

| 2003 14.0 6067HK6E (EGR) | 500hp@2100 1650ftlbs@1200 | No tuning options at this time | No tuning options at this time |

| 2004 14.0 6067HV6E (EGR) | 475hp@2100 1550ftlbs@1200 | No tuning options at this time | No tuning options at this time |

| 2001 23.9 R1227K12 | 1480hp@2360rpm | 3723ftlbs@1800rpm | – |

| 2002 31.8 R1627K22 | 1285hp@2110rpm | 3753ftlbs@1650rpm | – |

| 2002 31.8 R1637K35 | 1800hp@2360rpm | 4572ftlbs@1650rpm | – |

Estimated cost – DDEC IV programming/Tuning service

Triple On The fly Switchable Programming w/ install kit

Triple Play 3 setting or 2 setting on the fly switchable ECM programming, switch, harness and switch install kit. Pick three peak horsepower, max rpm, and peak torque settings. Parameter changes can be included and completed during this programming service provided requests were made before or when the ecm was first received by DCS

$1000 + return shipping

Single Non Switchable Programming

All Detroit programs are made to order so pick a peak horsepower, a maximum rpm, and pick a max torque. Parameter changes can be included and completed during this programming service provided requests were made before or when the ecm was first received by DCS

$800 + return shipping

Average job completion time is 2 business days If no other scheduled jobs are pending and when all needed engine and application information is provided before or at the start of the ecm software programming service.

Program Parameter changes & software Diagnostics

Unlike ecm software programming service the costs of both Software Diagnostic testing and Program Parameter service are dependent on the time spent receiving and reviewing any reported abnormality, request, or parameter change followed by the testing of software or changing of parameter values, reporting back findings or completed changes and ends after a customer side approval or acknowledgement. The only exception is when program parameter service requests are made at the start of or before the start of an ecm software programming/tuning service. When that happens the parameter changes will usually be considered to be part of the ecm software programming/tuning service. Parameter change requests and software Diagnostic testing requests made afterword regardless of circumstance will initiate the start of a new job and invoice. I send out a pre programmed message via text after the initial phone call requesting this information among other things before the start of a job to help avoid this but if for whatever reason it gets ignored then I’ll leave those settings the way they were. Costs tend to fall into the range of $150 – $600.

A few examples of program parameter changes

Fuel injector trim updates, Speed limiter, cruise control and tire size and/or rear end corrections, Automatic to manual transmission swaps, engine fan engagement temperature changes, Inputs, outputs and multiplexing changes. I send out a pre programmed message via text after the initial phone call requesting this information among other things before the start of a job.

.