Basic and overnight ECM hardware functionality testing

Basic 5 minute DDEC III ECM and DDEC IV ECM hardware functionality testing is usually part of the initial diagnostic testing that comes at the beginning of every hardware repair job. So, basic and overnight testing is not offered as a stand alone service unless requests for significantly more expensive specialized testing or exploratory testing has been made. Instead send it in for repair to fix whatever abnormal symptom or loss of function was observed and the job will start with a test of that function or a check for that abnormality. If a loss of ECM function or abnormality is observed during the basic 5 minute test the job will progress to a repair. Otherwise an overnight test will be done to see if an intermittent loss of function is recorded over a longer period of test time. Overnight tests add $100 – $150 to the job depending on the functions tested.

A Detroit Diesel DDEC III or DDEC IV ecm is integrated into the electrical system connecting both the engine and the application (truck) side. Fixing problems in this electrical system almost always start with the observation of an abnormal symptom or loss of function by the operator. That observation gets passed to a technician or someone else with physical access to the engine and application/vehicle side who can then rule out other possibilities in the wiring, sensors, switches, etc…before identifying the ecm as the cause of the problem. Shortcuts can be taken but yellow warning labels on the side of every DDEC III and DDEC IV since 1994 warn technicians of the risks they take when swapping a test ECM in place of another. The risk of injury/death is clear on most of the labels but what isn’t is the extra costs in time and money that shortcut could cause if “unintended results” cause the symptom or masks the symptom that leads to the technician misdiagnosing the ecm as the problem. Shortcuts save time and time is money. If the loss of function or abnormality isn’t observed during a basic 5 minute test because it’s intermittent or was misdiagnosed as an ecm problem, then the ECM testing will go to an overnight test, stop and/or go on to an internal inspection.

Microscope aided internal DDEC III-IV ECM inspection

Bench testing provides tests of ECM functionality during the testing but it does not provide any information on ECM condition or expected remaining component or function life. This is where a physical inspection of the circuit board and its components can help. Also with the service plate removed more advanced (and expensive) ecm tests such as thermal imaging tests can be done.

When an internal DDEC III-IV ECM inspection and a basic/overnight testing has not observed damage or recorded any loss of function

The best and least expensive option if you found a broken wire, sensor, or switch or had some other possible unexplored causes that are likely the cause of the observed loss of function or abnormality is to pay the cost of the first and overnight tests, the internal inspection and the return shipping then once that invoice is processed, we’ll mail your DDEC back so diagnostics of the engine and truck side can continue. The cost would be from $400 to $450 plus shipping.

Otherwise the other option is to go on to more specialized and advanced ecm tests such as internal component level tests

Specialized and advanced DDEC III and DDEC IV ECM functionality, symptom specific, component level and exploratory bench tests.

DCS can also a variety of more specialized ECM bench tests ranging from the external data monitoring of an engine input such as oil temperature to thermal imaging of a DDEC ecm during cold start up. We can even link multiple DDECs together to test the big 16-cylinder Detroits. Advanced and specialized ecm tests are mostly inside the ecm involving more test equipment, longer set up time, longer testing duration, component level tests and significantly higher costs. These tests can take longer than a repair job

If the conditions during the observed abnormality, loss of function, or symptom are unknown or not easily repeatable and have to this point not been observed during testing or visually observed damage during inspection to associated components then the only two options are to send it back and pay the $450 plus shipping in testing costs and get your ecm back or move up to the advanced and more specialized component level ecm tests. I don’t like getting into these unless you have done thorough diagnostics on the truck and engine side and have a datalink or telematics recording of what you did or the loss of functionality or abnormality that was observed. I’ve run these advanced ECM lab tests for application side engineers, +100ft yachts, fleet service managers, truck pullers, other ecm rebuild shops, and owner operators.

Thermal imaging is an option after an inspection

Oil trapped underneath top layer of laminate

Component oxidation often won’t act up when testing

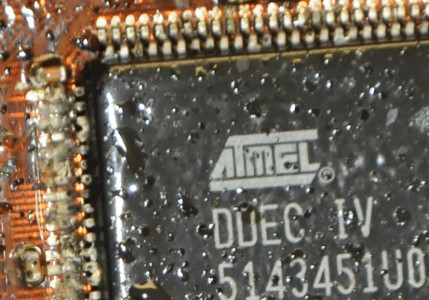

DDECs like this can be fully functional and test good despite being covered in oil. This is why an inspection is often a good idea after a test.

Didn’t have to spend any test time on this DDEC IV. A quick internal inspection was all that was needed to core it. When the damage is this bad and the ecm is getting cored and not getting sealed back up the inspection cost is $25

Black trace oxidation indicates a water intrusion problem.

Microscope aided internal DDEC III-IV ECM inspection

- Inspection and minor testing costs can sometimes be included in the cost of the repair.

- DDEC ECM internal inspections of the first layer can be useful for discovering components that have gone beyond their service life, past repairs or past and current oil – water – fuel intrusion, laminate damage and residual trace or component oxidation left behind that may not result in an observable abnormality or loss of function during ecm testing or operation.

Estimated cost $300 plus return shipping

DDEC III ECM and DDEC IV ECM testing

- Inspection and minor testing costs can sometimes be included in the cost of the repair.

- ECM bench tests ecm hardware functionality during the test. It cannot be used to predict future functionality conditions or life

- DDEC III and DDEC IV ECM testing evaluates ecm functionality during the testing period. Intermittent symptoms may not be observed during the testing period if the duration of the testing period is less than the frequency of the symptom.

- Intermittent symptoms may not be observed during the testing period if the conditions that trigger the loss of functionality or abnormality go unreported or are unknown preventing the ecm test conditions from being replicated

- Overnight and extended tests can improve the chances of catching a symptom that only occurs once a day. Testing can identify memory issues as well as well as other functions that fail to work after a few hours such as Jakes and injectors.